Rolls

Gontermann-Peipers is a well-known name in the international steel and aluminum industries. GP is synonymous with a wide range of wear-resistant and high-performance rolls of excellent durability, manufactured with the highest precision.

Particular highlights of GP’s product range include work rolls in HSS and semi-HSS grades and double-poured back-up rolls with final weights of more than 200 metric tons.

In addition to the manufacturing of rolls, we also offer complete after-market and consulting services, covering all aspects of the roll and its actual application in the mill. These activities are accompanied by continuous Research & Development on new roll materials, which we test and optimize in close cooperation with our customers at their facilities.

FORMING TECHNOLOGY

The forming process in a rolling mill is a crucial stage in the manufacturing chain of flat products, such as plate, sheet or strip. Whether for products used in shipbuilding, civil engineering and pipeline construction, or for airplane and automotive body sheets – Gontermann-Peipers rolls shape the world!

To meet the specific requirements of every application, a wide range of rolls and rolling mill types is needed. Therefore, GP's product portfolio includes virtually all types of rolls used in the steel and aluminum industries worldwide.

Whether work rolls for creating the highest surface quality, or backup rolls to support the mill’s maximum roll forces - Gontermann-Peipers supplies the technology ensuring optimal interaction between tooling and process to achieve the best possible final product for our customers.

The GP product portfolio comprises of a wide range of work and back-up rolls for steel rolling mills. Our roll configurator helps you find the perfect rolls for your requirements. If you are interested in our grooved rolls or rolls for aluminum rolling mills, please contact our sales department directly.

GP PRODUCT FINDER – THE EASY WAY TO FIND YOUR PERFECT ROLL

The GP product portfolio comprises of a wide range of work and back-up rolls for steel rolling mills. Our roll configurator helps you find the perfect rolls for your requirements. If you are interested in our grooved rolls or rolls for aluminum rolling mills, please contact our sales department directly.

Please select between hot rolling mill and cold rolling mill:

Hot rolling mill

In the hot rolling mill, the rolling stock undergoes its first forming stage. Hot slabs, blooms or billets are reduced and formed by rolling – via three different process routes – into plate, hot strip or sections.

SelectCold rolling mill

Part of the products from the upstream hot rolling process undergo a second forming stage in the cold rolling mill. For cold rolling, the rolling stock does not have to be reheated. Compared to hot rolling, the cold rolling process achieves smaller dimensions, higher dimensional accuracies, higher strengths and superior surface quality.

SelectSelect a rolling process:

Select a rolling mill type:

- Select a processing method:

- Reversing

- Continuous / Semi-continuous

- Select a processing method:

- Reversing

- Continuous

- Select a rolling mill type:

- Roughing mill

- Finishing mill stand

- Select a rolling mill type:

- Finishing mill stand

Select a rolling mill type:

- Select a rolling mill type:

- Plate mills

- Steckel mills

- Select a rolling mill type:

- Conventional hot strip mills (HSM)

- Compact hot strip mill (CSP, USP, ESP)

- Select a rolling mill type:

- Reversing Cold Mills (RCM, CCM)

- Skin Pass Mills (SPM, ISPM, DCR, HSPM)

- Tandem Cold Mills (TCM)

Select a mill stand:

- Mill stand type

- Roughing mill

- Roughing mill and finishing mill stand

- Mill stand type

- Roughing mill

- Finishing mill stand

- Mill stand type

- Two-high roughing mill

- Four-high roughing mill

- Edger

- Early finishing mill stands

- Final finishing mill stands

- Mill stand type

- Early finishing mill stands

- Final finishing mill stands

Rolls

WORK ROLLS

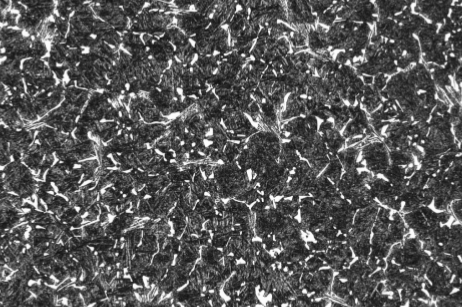

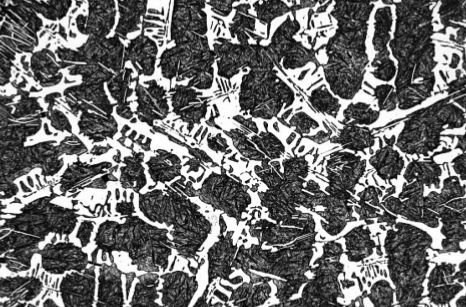

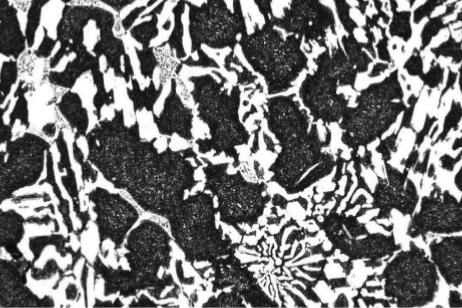

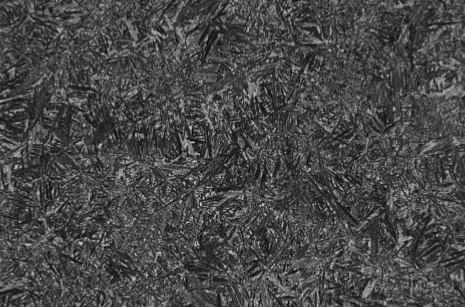

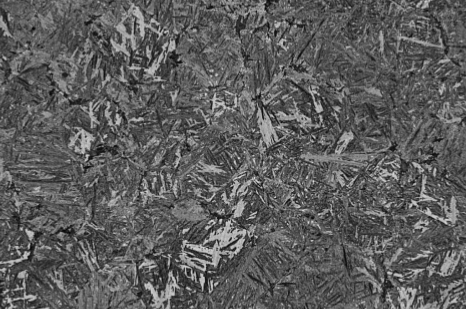

HVS78 (HSS)

This grade provides:

- Excellent wear resistance throughout the working layer

- Good hot working strength and very high resistance to firecracks

- Excellent surface performance

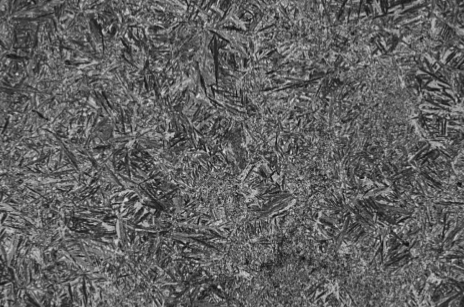

HVS75 / HVS76 (HSS)

This grade provides:

- Excellent wear resistance throughout the working layer

- Good hot working strength and very high resistance to firecracks

- Good surface performance

- High operational reliability

HVS70 / HVS71 (HSS)

This grade provides:

- Excellent wear resistance throughout the working layer

- Good hot working strength and very high resistance to firecracks

- Good surface quality

- High operational reliability

HCS-V (Semi-HSS)

This grade provides:

- Excellent wear resistance throughout the working layer

- Good hot working strength and very high resistance to firecracks

- Very low tendency for oxidization, resulting in excellent surface quality

- High reductions per pass and good biting conditions even at high hardnesses

- High operational reliability

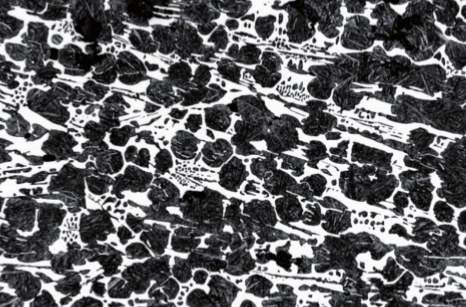

HCS-H (Semi-HSS)

This grade provides:

- Excellent wear resistance throughout the working layer

- Good hot working strength and very high resistance to firecracks

- Very low tendency for oxidization, resulting in excellent surface quality

- High reductions per pass and good biting conditions even at high hardnesses

- Stable mill conditions thanks to good thermal properties of the material

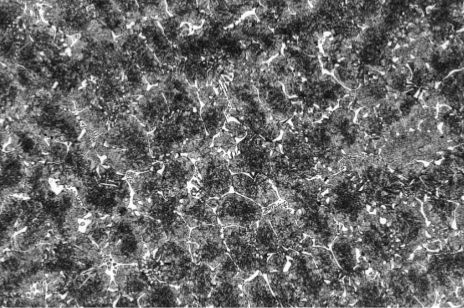

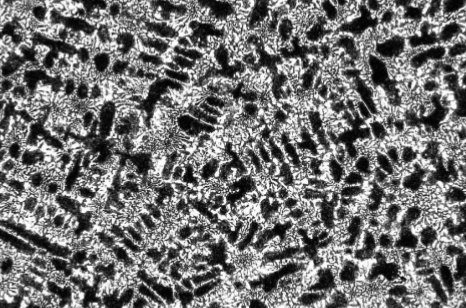

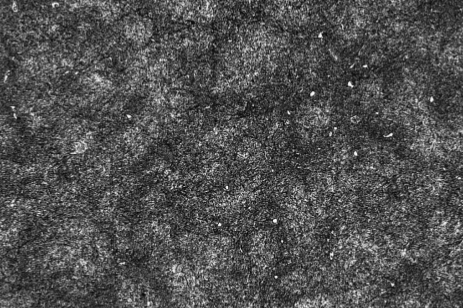

ASIIIM (ICDP enhanced)

This grade provides:

- Significantly enhanced wear resistance compared to conventional ICDP quality

- Only slight loss of hardness across the shell layer

- Only very slight tendency for sticking

- Excellent flatness

- Highly homogeneous surface

- High reliability in case of issues with mill stability

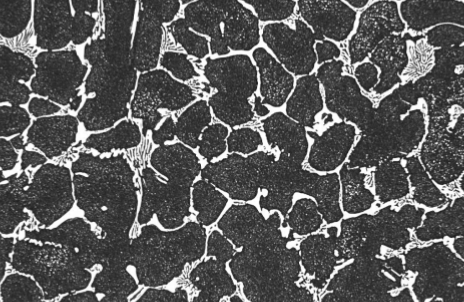

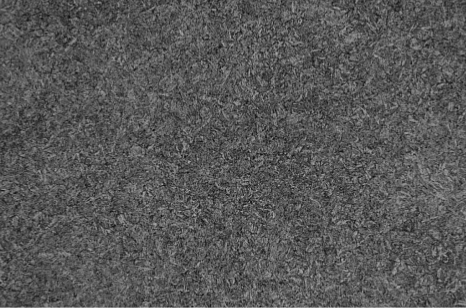

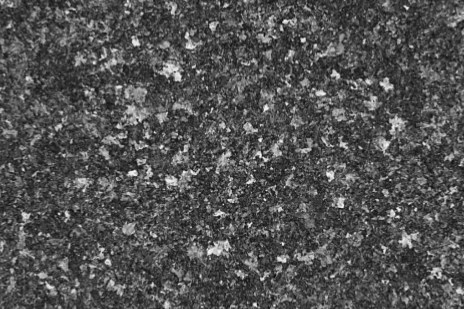

ASIII (ICDP)

This grade provides:

- Very low tendency for sticking

- High reliability in case of issues with mill stability

- Good flatness

- Highly homogeneous surface

- Only slight loss of hardness across the shell layer

ASIIICS (ICDP cpmpressive strength)

This grade provides:

- High compressive strength

- High reliability during long campaigns

- High reliability in case of issues with mill stability

- Very low tendency for sticking

- Good flatness

- Highly homogeneous surface

- Only slight loss of hardness across the shell layer

ASI80XX (HiCr Steel)

This grade provides:

- Good wear resistance throughout the working layer

- Good hot working strength

ASI80X (HiCr Steel)

This grade provides:

- Good wear resistance throughout the working layer

- Good hot working strength and high resistance to firecracks

- Low tendency for oxidization

- High reductions per pass thanks to good biting conditions

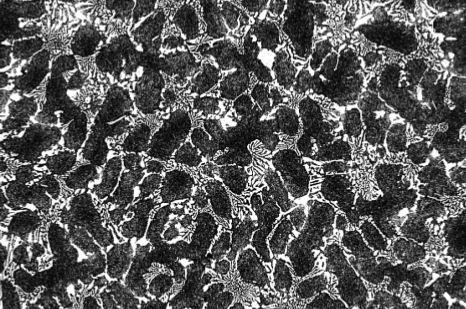

ASII100XX (HiCr Iron)

This grade provides:

- Excellent wear resistance throughout the working layer

- Good tempering properties and good resistance to soft spots

ASII80XX (HiCr Iron)

This grade provides:

- Excellent operational reliability

- Good wear resistance throughout the working layer

- Good hot working strength and high resistance to firecracks

ASII70XX (HiCr Iron)

This grade provides:

- Excellent wear resistance throughout the working layer

- Easy to grind

- Extended campaign lengths

- Can be used even without the need for chrome plating

- Good tempering properties and good resistance to soft spots

- Low tendency for particle sticking

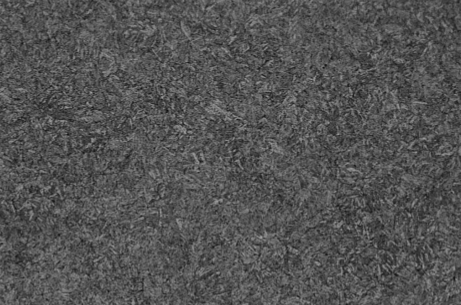

GP 350 / 450 / 550 (Graphitic Steel)

This grade provides:

- High resistance to firecracks

- Good wear resistance

- Good surface quality

AICMO (Cast Steel)

This grade provides:

- Good wear resistance

- Good weldability

- Very good operating safety even with deep grooves

Typical application:

- Rolling of sections

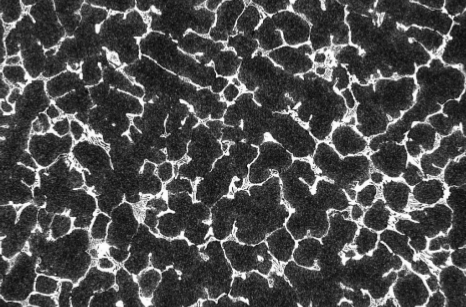

BACK-UP ROLLS

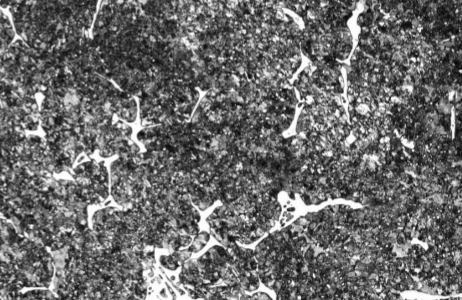

ASTI90X (8% Cr)

This grade provides:

- Excellent wear resistance throughout the working layer

- Especially when running against textured work rolls

- Good corrosion resistance

- Constant hardness throughout the entire roll shell

AST80X (5% Cr)

This grade provides:

- Good wear resistance throughout the working layer

- Constant high hardness throughout the entire roll shell

- Good corrosion resistance

- Stable roll-gap geometry even during long campaigns

- High stiffness

Advantageous residual compressive stress distribution in the roll shell and in the fillet area assures high resistance to spalling and fatigue cracks in the heavily stressed fillet area.

AST70X (5% Cr)

This grade provides:

- Good wear resistance throughout the working layer

- Constant high hardness throughout the entire roll shell

- Good corrosion resistance

- Stable roll-gap geometry even during long campaigns

- High stiffness

Advantageous residual compressive stress distribution in the roll shell and in the fillet area assures high resistance to spalling and fatigue cracks in the heavily stressed fillet area.

AST83 (3% Cr)

This grade provides:

- Stable roll-gap geometry even during long campaigns

- Good wear resistance throughout the working layer

- High stiffness

- Good corrosion resistance

- Virtually constant hardness throughout the entire roll shell

Advantageous residual compressive stress distribution in the roll shell and in the fillet area assures high resistance to spalling and fatigue cracks in the heavily stressed fillet area.

AST73 (3% Cr)

This grade provides:

- Stable roll-gap geometry even during long campaigns

- Good wear resistance throughout the working layer

- High stiffness

- Good corrosion resistance

- Virtually constant hardness throughout the entire roll shell

Advantageous residual compressive stress distribution in the roll shell and in the fillet area assures high resistance to spalling and fatigue cracks in the heavily stressed fillet area.

AST80 (2% Cr)

This grade provides:

- Stable roll-gap geometry even during long campaigns

- High stiffness

- Good wear resistance throughout the working layer

- Virtually constant hardness throughout the entire roll shell

Advantageous residual compressive stress distribution in the roll shell and in the fillet area assures high resistance to spalling and fatigue cracks in the heavily stressed fillet area.

AST70 (2% Cr)

This grade provides:

- Good wear resistance throughout the working layer

- Stable roll-gap geometry even during long campaigns

- High stiffness

- Virtually constant hardness throughout the entire roll shell

Advantageous residual compressive stress distribution in the roll shell and in the fillet area assures high resistance to spalling and fatigue cracks in the heavily stressed fillet area.

AST60 (2% Cr)

This grade provides:

- Good wear resistance throughout the working layer

- Stable roll-gap geometry even during long campaigns

- High stiffness

- Virtually constant hardness throughout the entire roll shell

Advantageous residual compressive stress distribution in the fillet area assures high resistance to fatigue cracks in the heavily stressed fillet area.

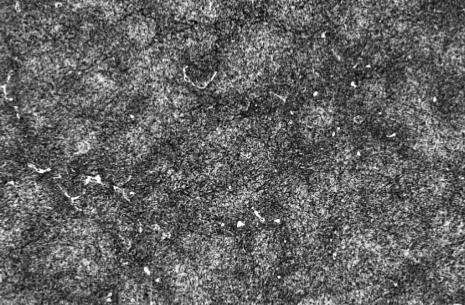

ASTIII80 (ICDP)

This grade provides:

- Low tendency for fin formation

- Good wear resistance throughout the working layer

Produkt Anfragen