CAST PRODUCTS

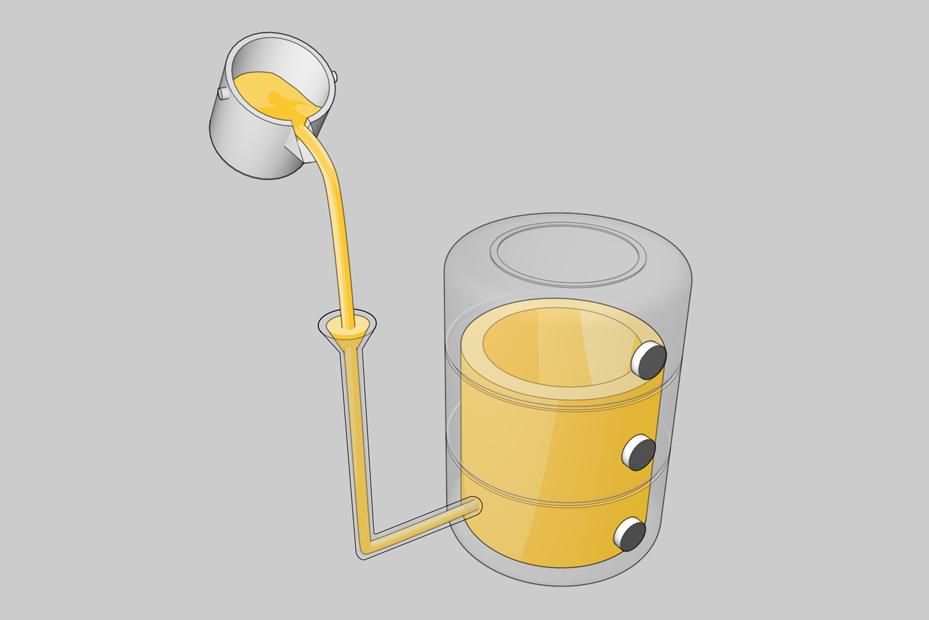

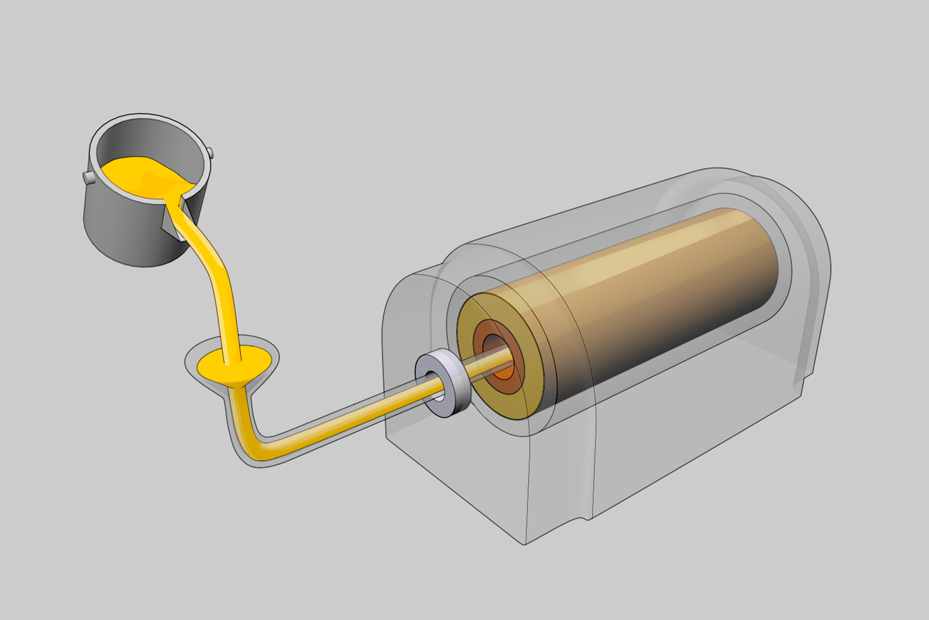

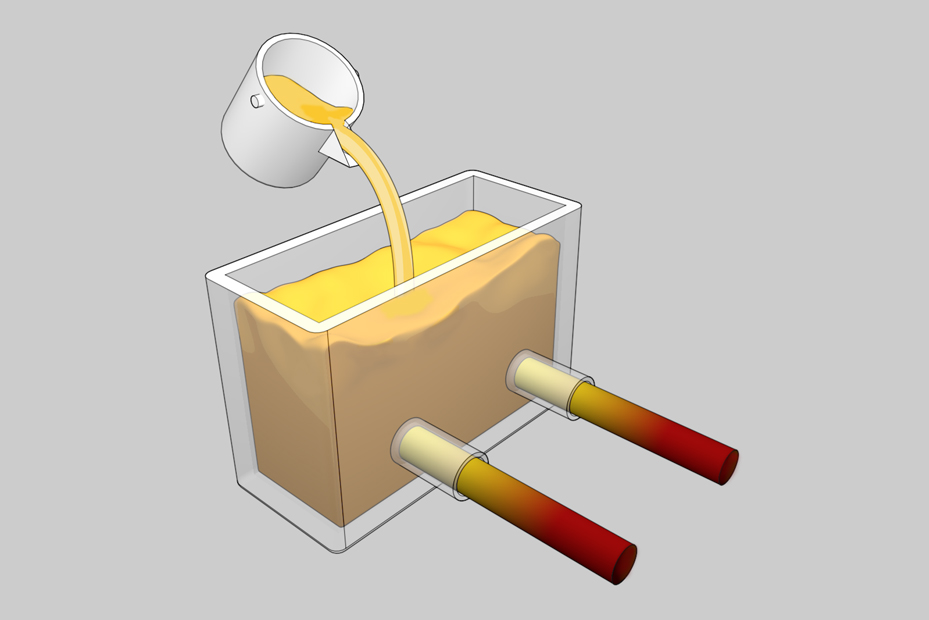

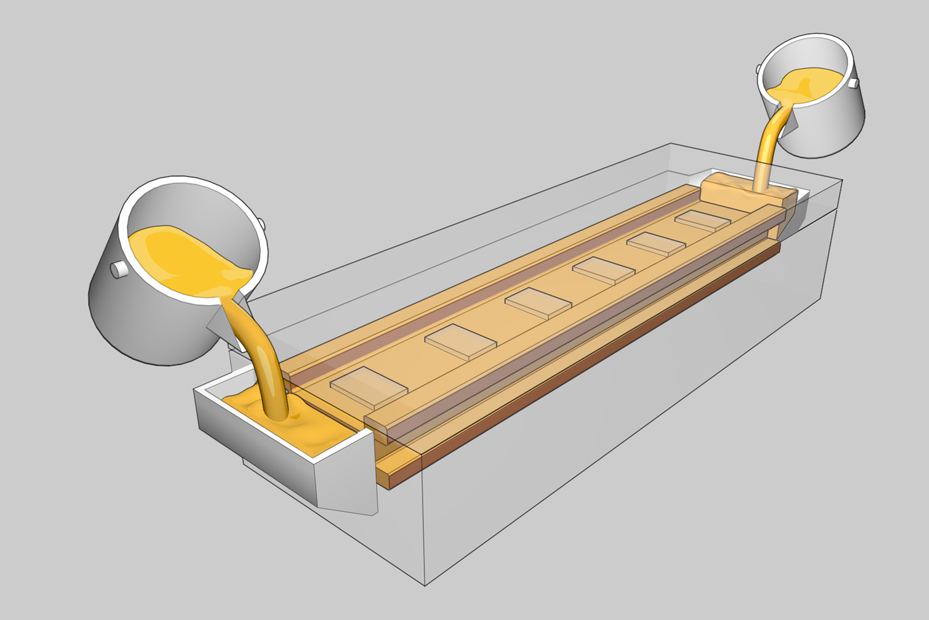

When your machine designs demand outstanding precision, durability and need to be cost-efficient, we are the perfect partner. Our range of casting processes assures the most varied range of optimization potentials, combined with maximum design flexibility and superior machinability, to guarantee that the components we produce comply precisely with the highly specific requirements of your engineering task. With our double-pour casting processes we produce components that combine materials of different properties. This gives you the flexibility to optimize functional properties – in many cases, seemingly contradictory ones - independently within a single component. As a foundry with an extensive range of machining capacities, our customers can choose the optimal product along the full depth of the value chain.

PRODUCT PROPERTIES

Our cast-iron materials cover a wide range of outstanding properties. Beyond those specified in the relevant standards, such as tensile strength, yield strength and hardness, we have continuously developed and further enhanced the properties to match the needs of each specific industry in the course of many years of experience. By applying special heat treatment processes, for example, we achieve extremely good, homogeneous microstructures that exhibit high density and minimum porosity.

Our customers greatly appreciate the outstanding properties of our castings, since they enable the use of lighter designs – a very important aspect in hydraulic engineering, for example. Comprehensve Quality Control throughout our entire production chain guarantees that our customers can be sure of receiving products of consistent high quality.

APPLICATIONS

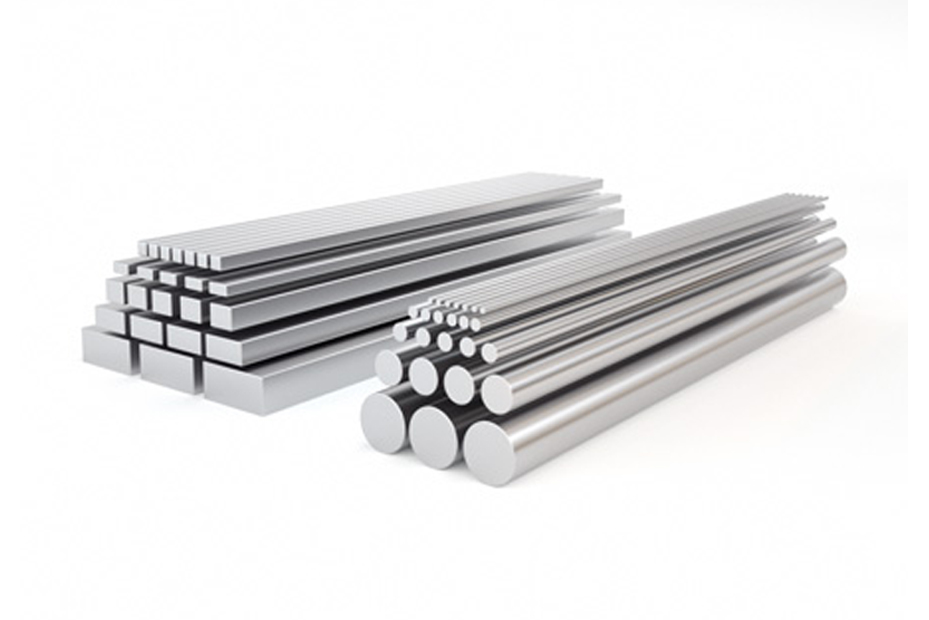

The applications for our products are as individual and specialized as our customer base. From cast round and square bars for use as blanks, from large ingots up to highly complex finished components – Gontermann-Peipers can cast the perfect solution you are looking for. Whether you need a straight-forward cast-iron product, a special alloy grade or even a double-poured casting for a highly specific application. We are always pleased to discuss individual solutions with our customers. Numerous companies and industries are drawing from our competence and expertise, in mechanical engineering, hydraulics, pump and compressor manufacturing, and many other sectors.

No matter what your application, we can produce everything for you from a single lapping wheel to small numbers of cylinder liners, large series of several hundred items or even thousands of cast ingots. We are always happy to discuss specific issues with our customers and develop the ideal solution together with you.

Chill-cast products as cast/cut to length/pre-machined

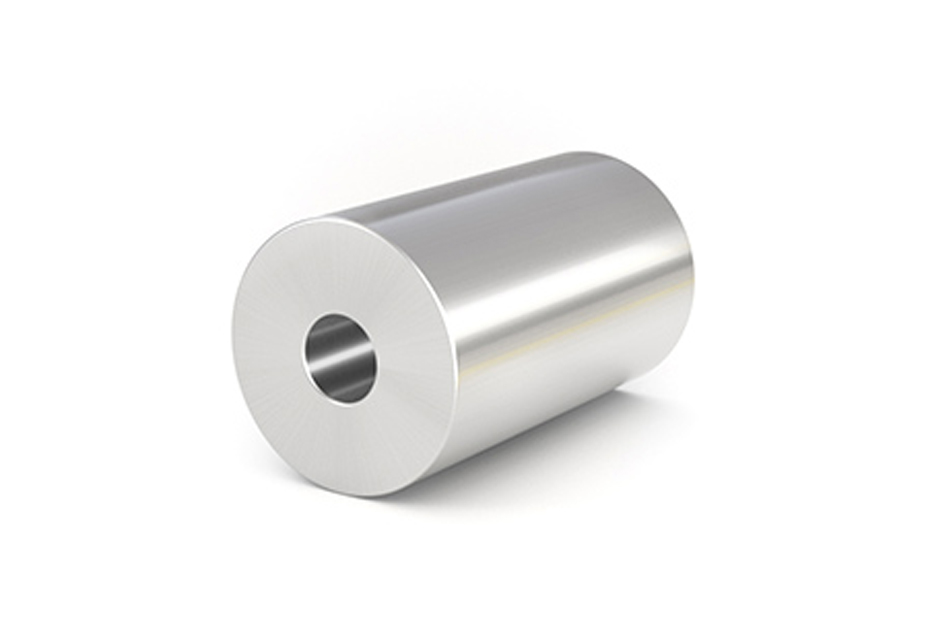

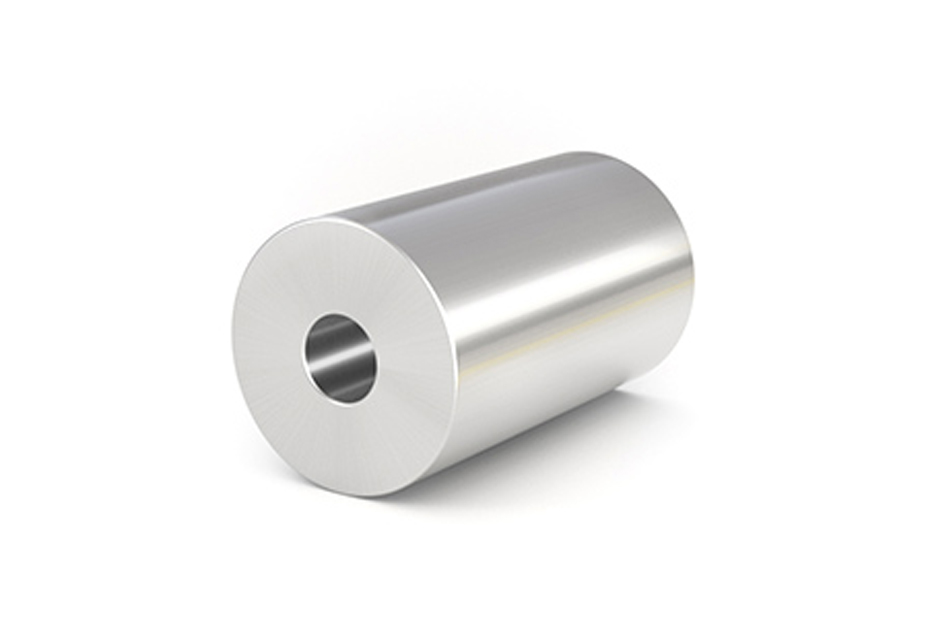

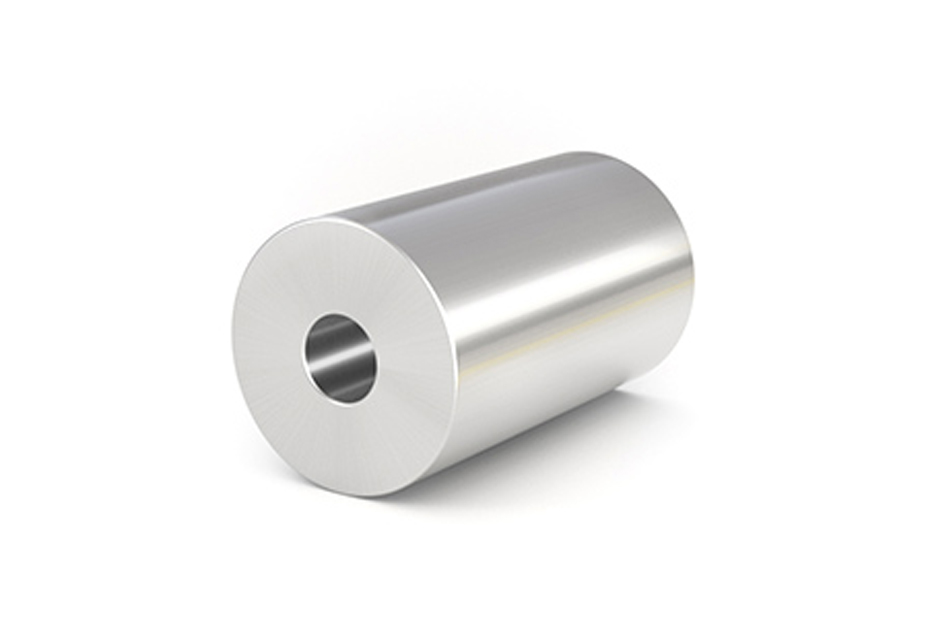

Pre-machined sleeves

Ready-to-install cylinder liners for compressors and engines

Pre-machined sleeves

Ready-to-install cylinder liners for compressors and engines

CONTINUOUS CASTING

Our decades of experience and continuous development of the continuous casting of iron enable us to produce cast-iron components that possess a very dense and fine-grained microstructure, making them ideally suited for high-speed industrial downstream processing and assuring the reliable attainment of the specified tolerances.

Strangguss

Continuous-cast products as cast/cut to length/pre-machined

Pre-machined sleeves

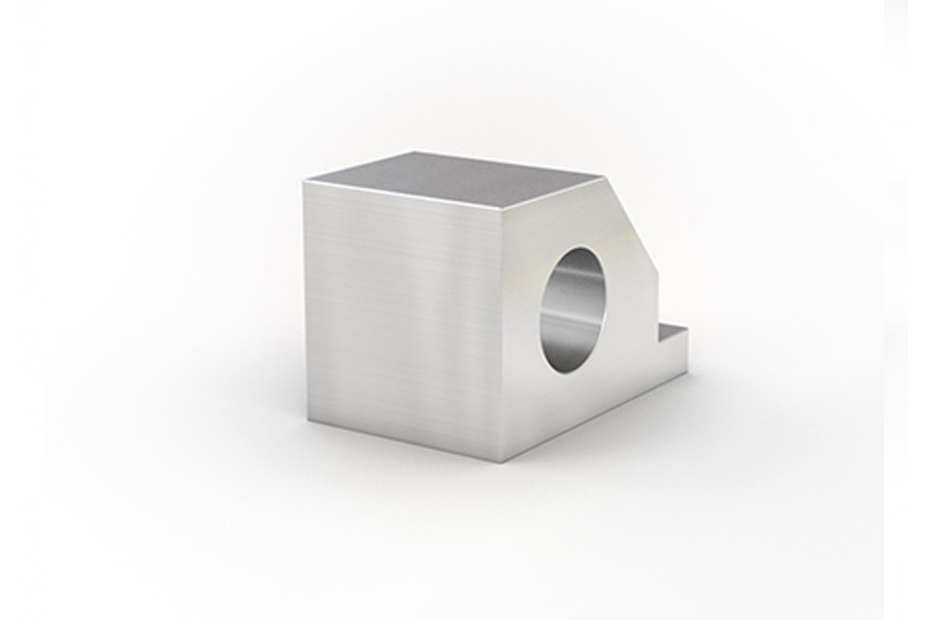

Machine-tool castings

Oversized components, such as machine beds, columns and cross-beams for special machinery