Mechanical engineering

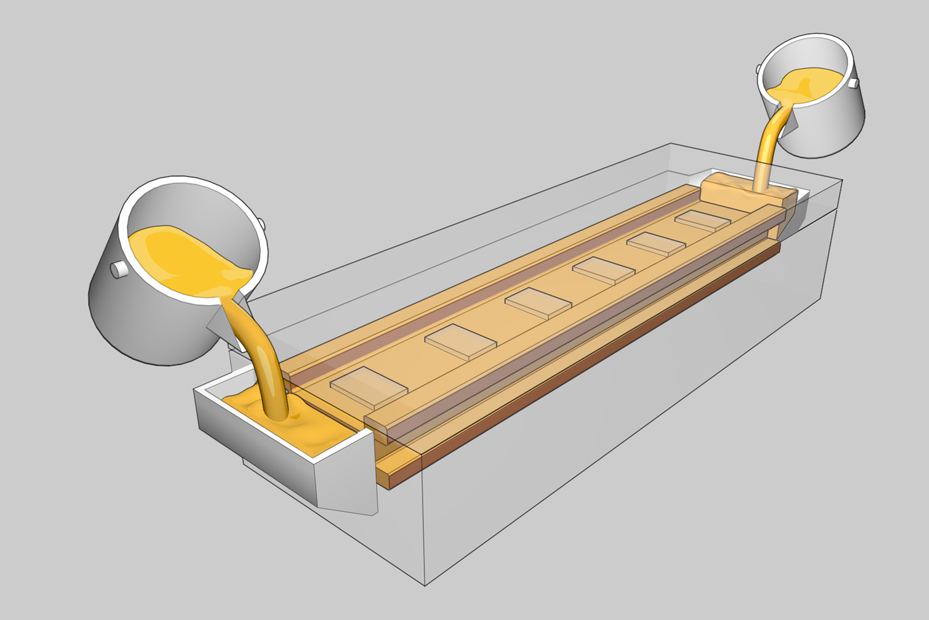

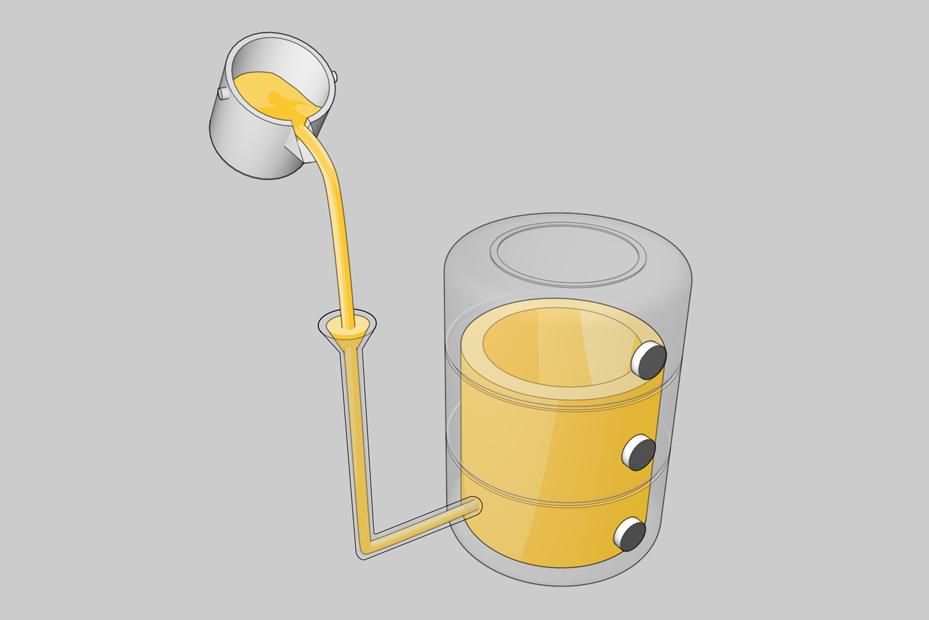

Cast materials are available in an extremely broad range of grades and assure excellent thermal conductivity, failure tolerance and vibration-absorption properties, making them the first choice for numerous mechanical-engineering applications. Building on our many years of experience in the casting of components that are required to withstand extremely high in-service stresses, we specialize, among other things, in the production of large machine beds. As a design and development partner, we work closely with our partners and customers to design most optimized machines using our customized cast products. Due to the maximum design flexibility assured by our casting processes, we are able to integrate various functions within a single component as early as the design phase. The double-pour casting process gives us the flexibility to develop solutions that not only meet your technical requirements but also deliver optimum cost-efficiency.

Continuous casting

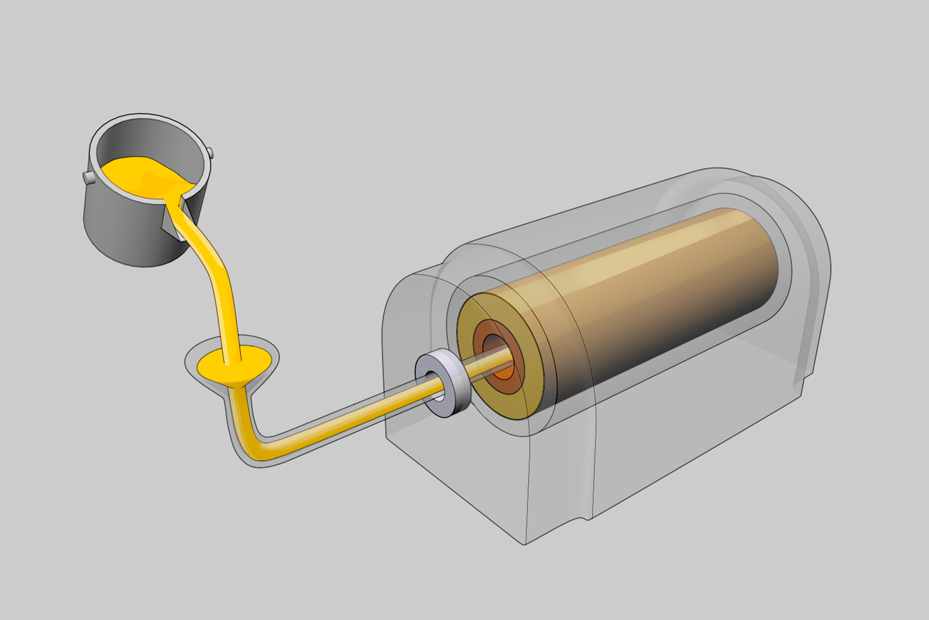

Our decades of experience and continuous development of the continuous casting of iron enable us to produce cast-iron components that possess a very dense and fine-grained microstructure, making them ideally suited for high-speed industrial downstream processing and assuring the reliable attainment of the specified tolerances.

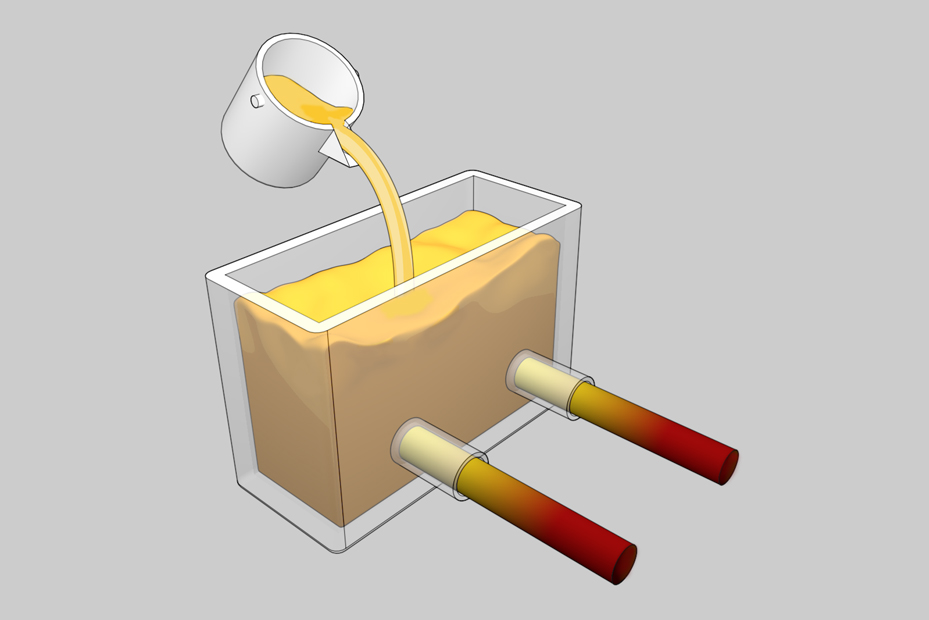

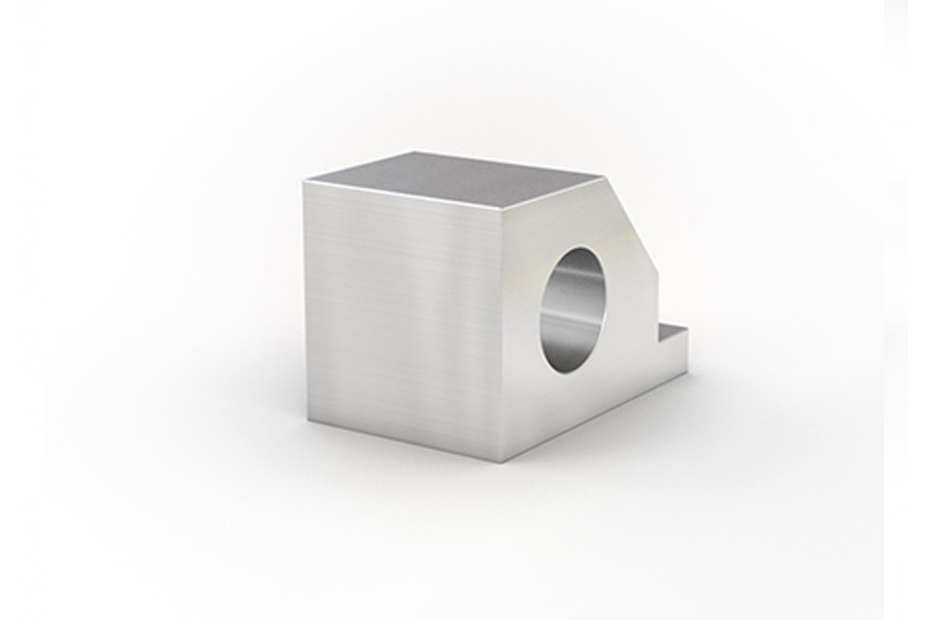

Machine parts