Chill Casting

In the chillcasting process, i.e. a casting method using cooled molds and dies, the metal can solidify at high, precisely controlled rates. This and subsequent heat treatments enable the production of tailor-made materials with mechanical properties optimized specifically for their future functions. From our chillcast products, components are manufactured in a wide range of shapes and grades for applications as demanding as machinery and hydraulics, where they assure safe and reliable operation.

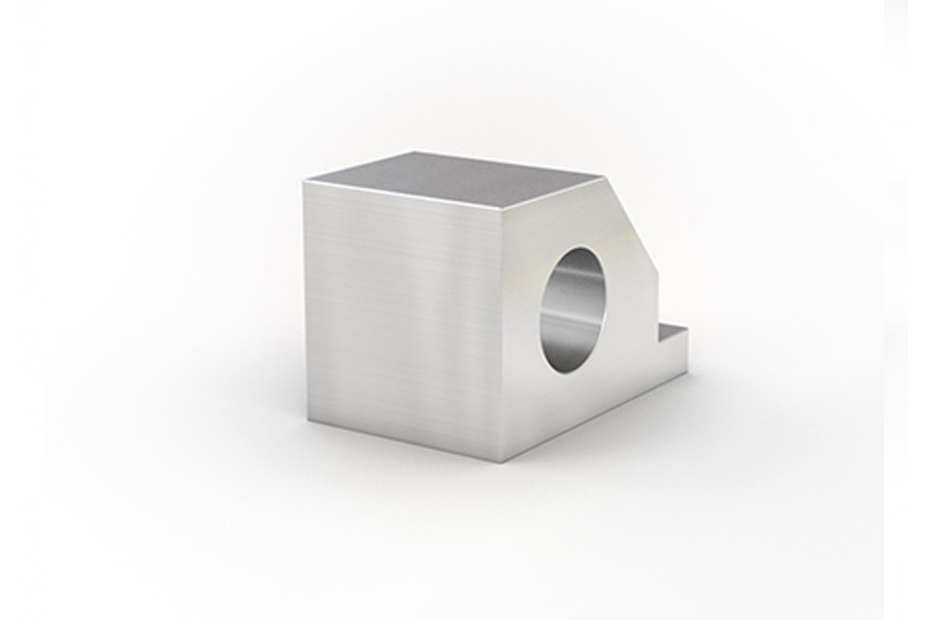

Chill-cast products as-cast/sawn/pre-machined

Pre-machined sleeves

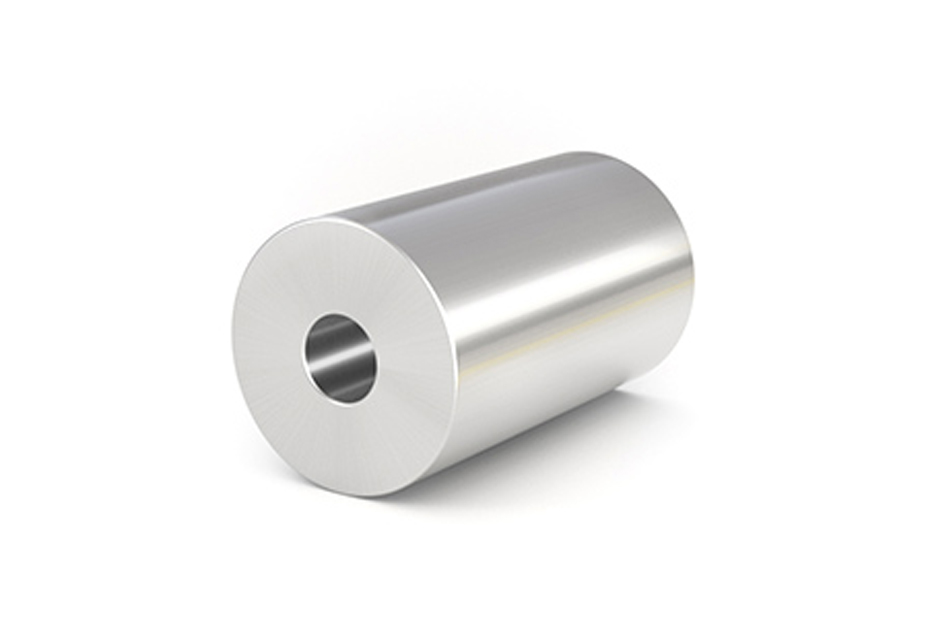

Ready-to-install cylinder liners

for compressors and engines

Chill-cast products as-cast/sawn/pre-machined

Billets and blooms, milled on 4 sides

Ingots, machined on six sides

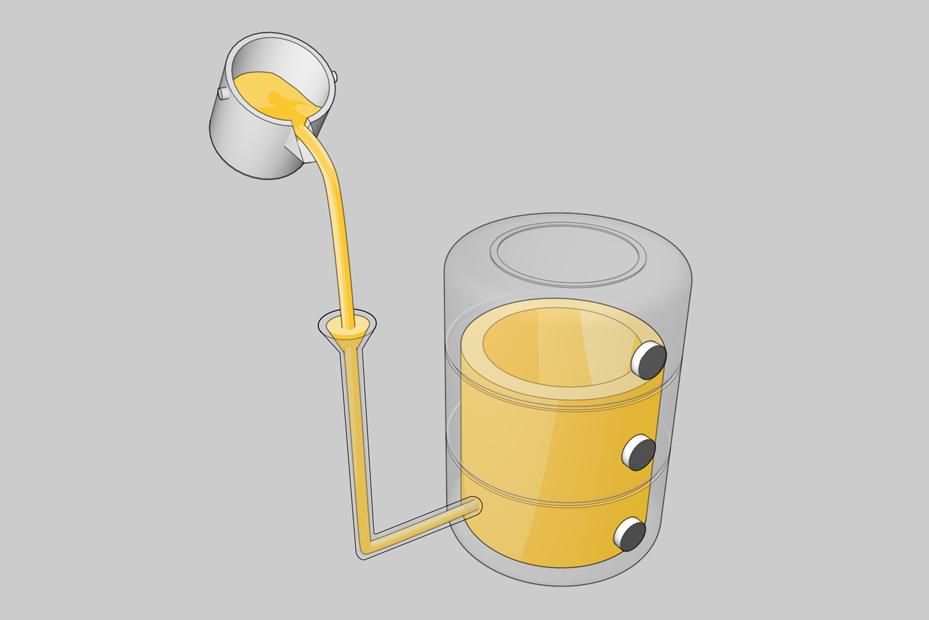

High-pressure grinding rolls (HPGRs) and roll sleeves

double-pour cast for the food industry, e.g. for chocolate and flour production