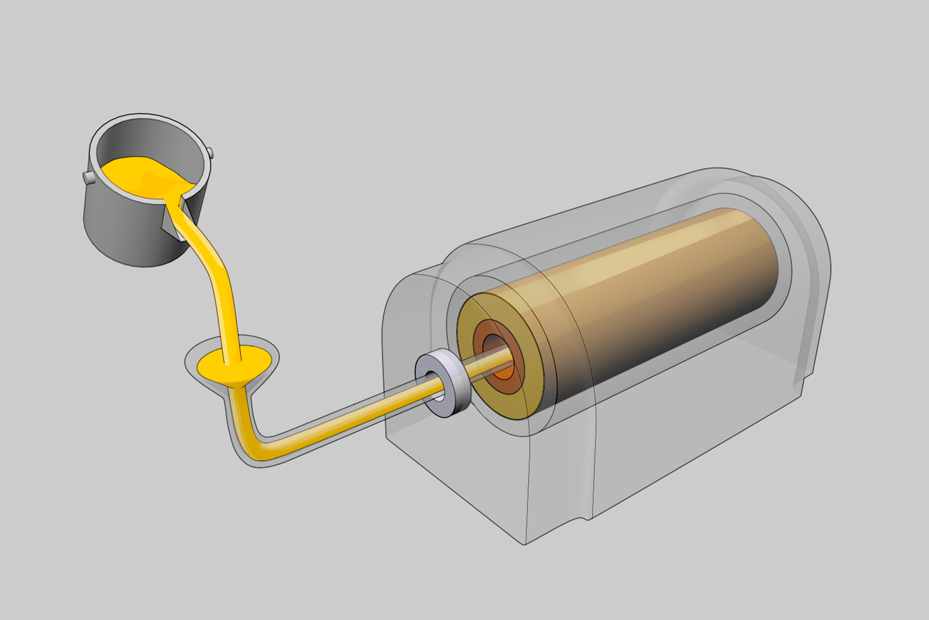

Spin casting

In spin casting, cast iron is poured into a spinning mold. The molten metal is thrust against the mold wall by centrifugal force. The rapidly solidifying metal is characterized by a fine-grained microstructure with extremely good mechanical properties. This makes spin cast iron an ideal material for machine components. With our versatile range of machining and treatment options, such as sawing, milling, turning, honing and hardening, we can supply our customers products in precisely the condition desired and needed to assure dependable in-service performance of the component. Using our double-pour casting processes, we can even produce components that combine materials of different properties. This gives you the flexibility to optimize functional properties within a single component.

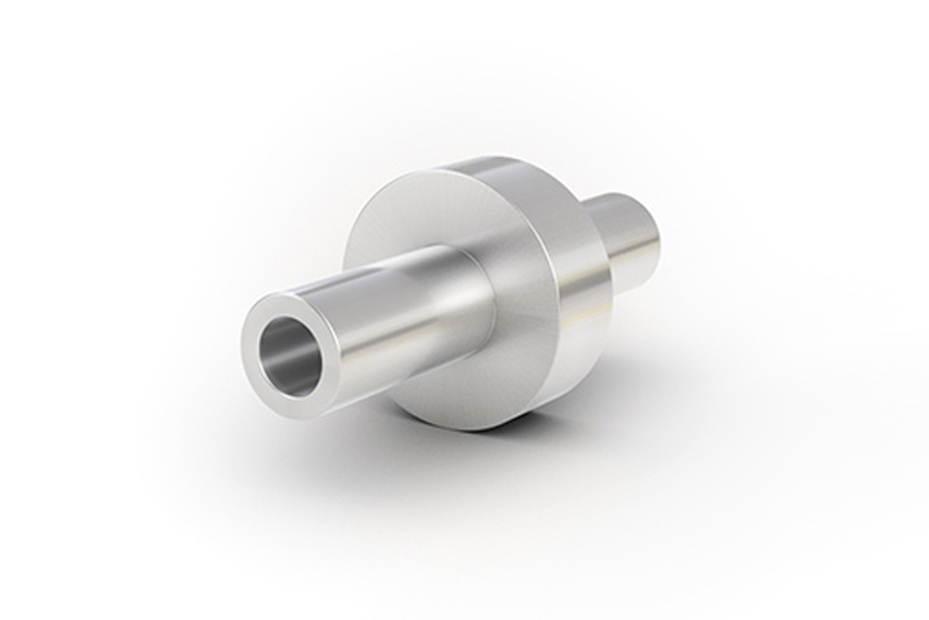

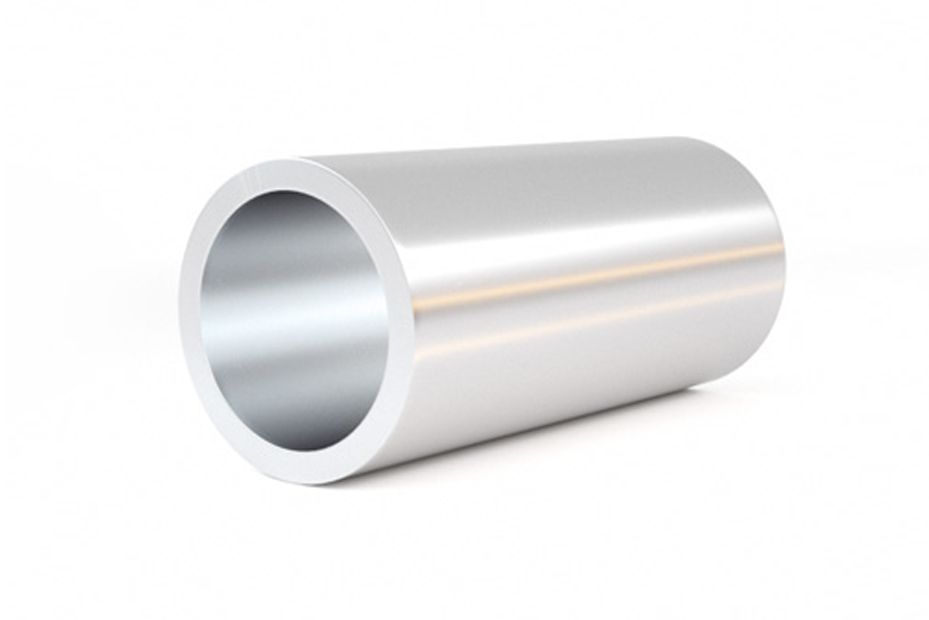

Ready-to-install cylinder sleeves

for compressors and engines

Pre-machined sleeves

High-pressure grinding rolls (HPGRs) and roll sleeves

double-pour cast for the food industry, e.g. for chocolate and flour production

Grinding rollers and HPGRs (high-pressure grinding rolls)

double-pour cast for use in cement production and crushing of glass and minerals