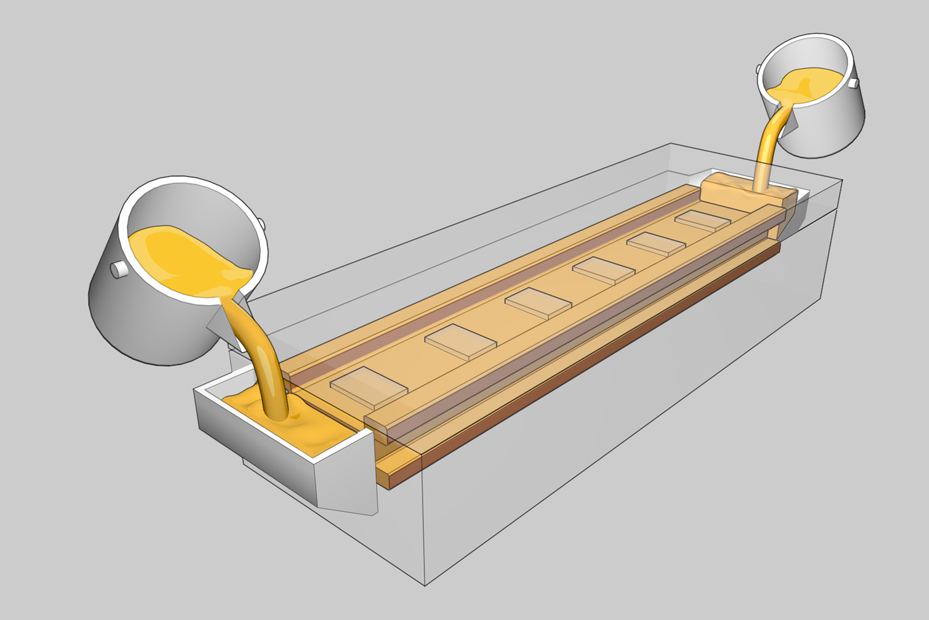

Hand-mold casting

For large components with complex geometries weighing up to 160 metric tons, we use the hand-mold casting process, which enables us to produce castings with geometrically optimized structures. The construction of the molds requires excellent artisanal skills. The sand cores have to be molded down to the last detail to be able to cast sophisticated high-cavity components for machinery equipment and other demanding applications. We also apply latest technology, such as simulation of the casting and solidification processes and FEM calculations, to support us in achieving optimum results in the most efficient way. We stay in dialog with the customer throughout the mold designing process because it very often turns out that during this phase components can be further optimized, last but not least with a view to weight reduction. With hand-mold casting, components containing both very thin and very thick sections can be manufactured near net shape in weights ranging between 10 and 160 metric tons. Our hand-mold casting expertise guarantees that your machinery will run smoothly and dependably - for a very long time into the future.

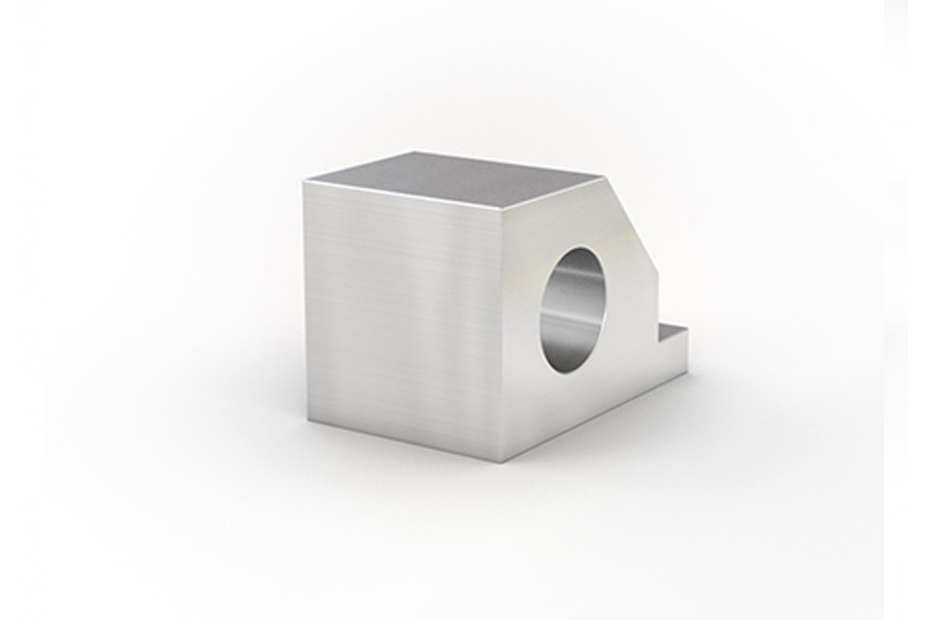

Machine tool casting

Oversized components, such as machine beds, columns and cross-beams for special machinery